ELINDUCT A301M

Low Temperature Curing,Conductive Die Attach Adhesive

Key Features

● Thixotropic, Low flow during cure;

● Excellent electric properties, Reliable electronic assemblies;

● Fast curing at low temperature, High output and low stress.

Discuss your application Request a Technical Data Sheet Request an MSDS

Product Description

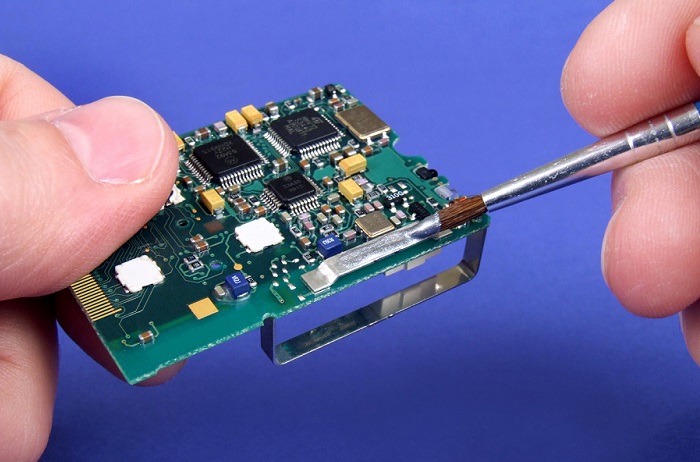

ELINDUCT® A301M die attach adhesive has been formulated for use in high throughput die attach applications. This material is designed to minimize stress and resulting warpage between dissimilar surfaces.

ELINDUCT® A301M adhesive can be snap cured using directed heat energy or hot plate curing techniques. In conventional box or convection conveyor oven curing, it will cure rapidly at temperatures as low as 80ºC.

Applications

ELINDUCT® A301M is special designed for die attach or electric conductive bonding which require low curing temperature or high throughput, like CMOS module and touch panel.

Instructions For Use

Thoroughly read the information concerning health and safety contained in this bulletin before using. Observe all precautionary statements that appear on the product label and/or contained in individual Material Safety Data Sheets (MSDS).

To ensure the long term performance of the bonded assembly, complete cleaning of the substrates should be performed to remove contamination such as oxide layers, dust, moisture, salt, and oils which can cause poor adhesion or corrosion in a bonded part.

This material is designed for pin transfer, dot dispensing, and/or syringe applications. Dispense the desired amount of material and place die into deposit using downward force to achieve desired bondline.

Pls contact E-Linking Technical Service Department for detailed recommendation on adhesive application, including dispensing.

Packaging

| |||||

| Syringes |

Products

OurLatest Product

-

Specially formulated one com...

-

Two component epoxies featur...