ELINBOND S111

RTV-1 Silicone Rubber Adhesive and Sealant

Key Features

● One component,low stress

● Excellent primerlessa dhesion,Structural bonding to a wide variety of substrates

● Excellent weatherability,use in harsh environment condition.

Discuss your application Request a Technical Data Sheet Request an MSDS

Product Description

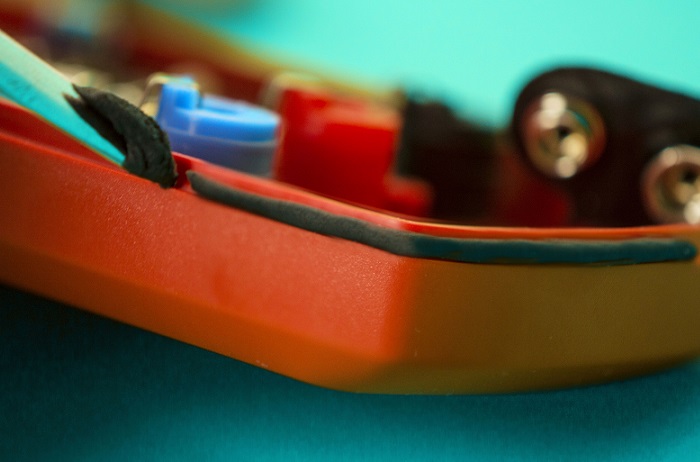

ELINBOND S111 is a one-component, netural silicone adhesive sealant with very good mechanical properties, which cures at room temperature under the influence of atmospheric moisture. It is a ready-to-use paste and provides primerless adhesion to a wide range of substrates. ELINBOND S111 cures to a medium hardness and elastic bondline with good resistance to heat, UV light, weather and excellent dielectric properties.

Applications

ELINBOND S111 is general-purpose adhesive and sealant for industry. It’s special designed for bonding metal, ceramics, glass, rubber, leather and nylon substrates.

Instructions For Use

Thoroughly read the information concerning health and safety contained in this bulletin before using. Observe all precautionary statements that appear on the product label and/or contained in individual Material Safety Data Sheets (MSDS).

To ensure the long term performance of the bonded assembly, complete cleaning of the substrates should be performed to remove contamination such as oxide layers, dust, moisture, salt, and oils which can cause poor adhesion or corrosion in a bonded part.

All surfaces must be clean and free of contaminants that will inhibit the cure of ELINBOND S111. Examples of inhibiting contaminants are sulfur containing materials, plasticizers, urethanes, amine containing materials and organometallic compounds – especially organotin compounds. If a substrate’s ability to inhibit cure is unknown, a small scale test should be run to determine compatibility. For information on proper substrate preparation, refer to the reprint "Good Adhesive Bonding Starts With Surface Preparation" available from E-LINKING.

Apply the adhesive to all surfaces to be bonded and join together. In most applications only contact pressure is required.

Packaging

| |||||

| Cartridge |

Request Information

Discuss your application Request a Technical Data Sheet Request an MSDS

Products

OurLatest Product

-

Specially formulated one com...

-

Two component epoxies featur...